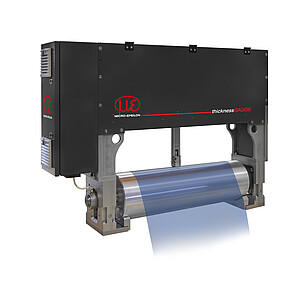

Micro-Epsilon

More precision for the world of tomorrow

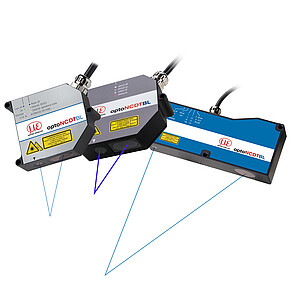

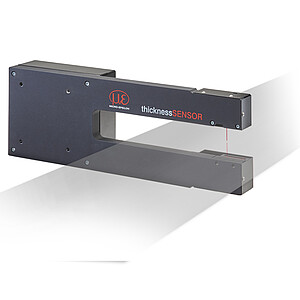

As a leading manufacturer of precision sensor technology, we are shaping the future. Our systems are used whenever accuracy and performance are crucial to success. In machine building and automation as well as in satellite technology and in the production of next-generation batteries and computer chips. As a globally active group of companies, we are making a decisive contribution to the world of tomorrow - and have been doing so for more than 56 years.

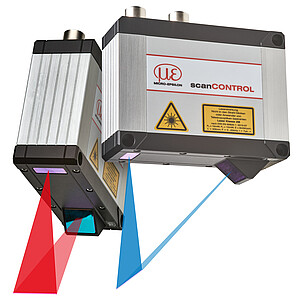

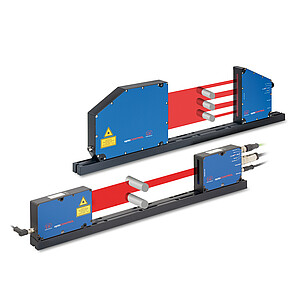

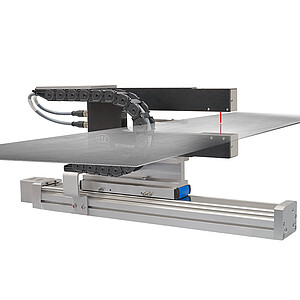

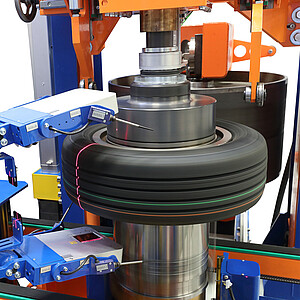

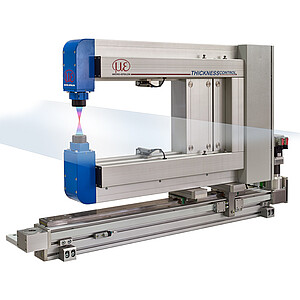

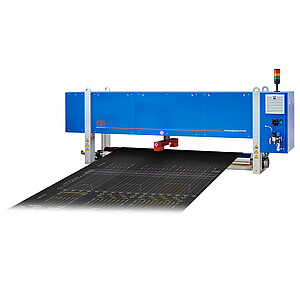

High performance in all industries

Whether for quality assurance, predictive maintenance, process and machine monitoring or advanced automation – sensors from Micro-Epsilon make a significant contribution to improving products and processes in a wide range of industries. As a result, efficiency gains are achieved in production and the cost of materials, waste and energy is significantly reduced.

High technology

What sounds like the future is already at the heart of what we do today. Hundreds of satellites orbit the earth at low altitudes and provide fast internet connections around the world.

Our tilting mirror systems enable secure laser communication. This is possible at an altitude of over 500 km, at speeds of over 25,000 km/h and distances of up to 5000 km.

These sensor-actuator systems are another milestone in our company's history and demonstrate our ability to turn top performance into series products. With pioneering technologies such as these, we are consolidating our leading position in sensor technology.

More Precision

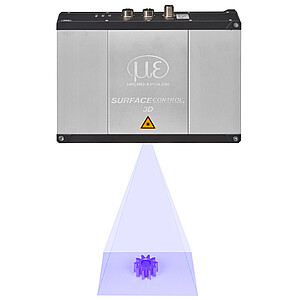

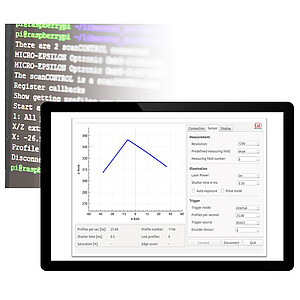

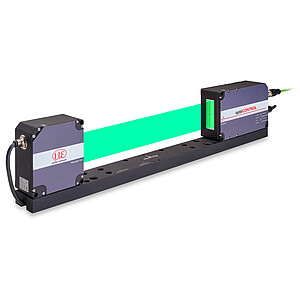

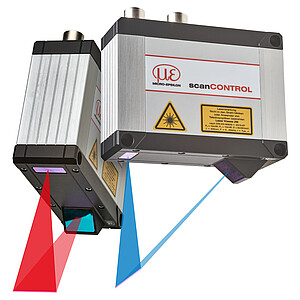

We strive for greater precision in our products and thus promote innovation. Our displacement sensors achieve resolutions down to the sub-nanometer range, which is less than a millionth of a millimeter. These are used, for example, in semiconductor lithography machines in ultra-high vacuum.

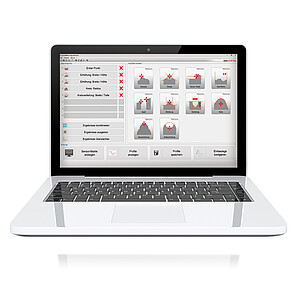

In order to implement such high performance in series products, we rely on the competence network within our group of companies. Consulting, product development, application, electronics, optics, image processing, micromechatronics, simulation, software, system integration, production and quality - all from a single source.