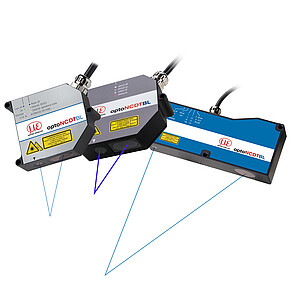

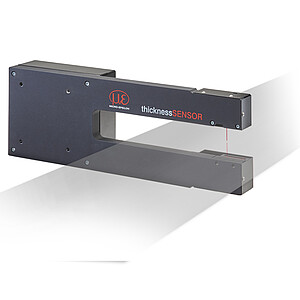

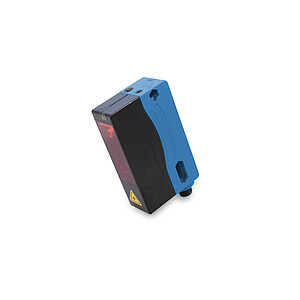

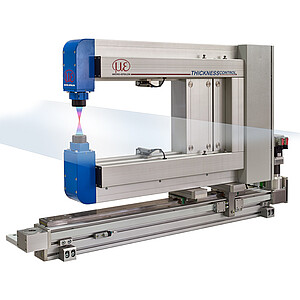

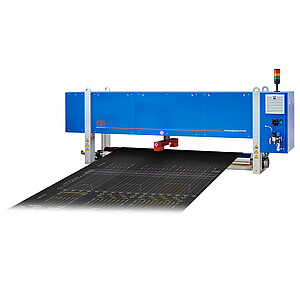

Laser sensors can be used to dynamically and precisely determine the displacement, distance, and position on various surfaces. The optoNCDT 1900 sensor is a particular highlight in Micro-Epsilon's product portfolio. It delivers precise measurement results with high resolution and linearity for numerous measurement tasks in factory automation. The integrated high-performance controller enables fast and high-precision measurement value processing and output.

Thanks to integrated interfaces such as EtherCAT, EtherNet/IP, and PROFINET, the optoNCDT 1900 is ideal for use in networked factories. Users benefit from real-time data without delay and with reduced installation and wiring effort. Fields of application include advanced automation, the automotive industry, 3D printing, and coordinate measuring machines. The sensor covers various measuring ranges from 2 to 750 mm with a measuring rate of 10 kHz and measures quickly and precisely on all surfaces. Advanced Surface Compensation with innovative algorithms ensures stable measurement results, even on shiny metallic, slightly reflective, or transparent surfaces.

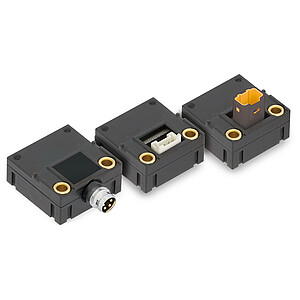

Micro-Epsilon now offers additional configuration options for measurement tasks involving larger quantities. For example, Micro-Epsilon assembles cables to the desired length or configures connectors according to customer requirements. In addition, the desired sensor settings for series applications can already be parameterized in the factory, eliminating the need for the customer to adjust the sensor.