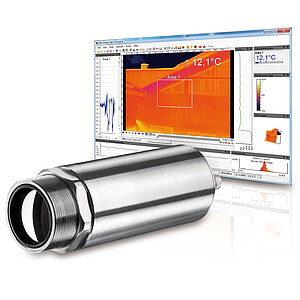

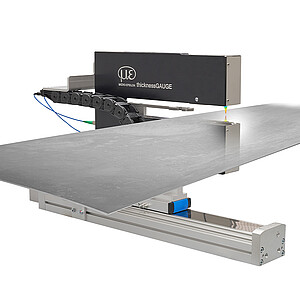

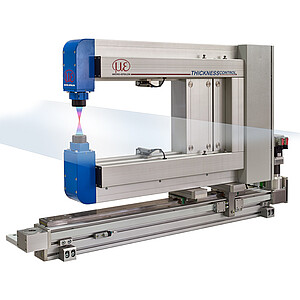

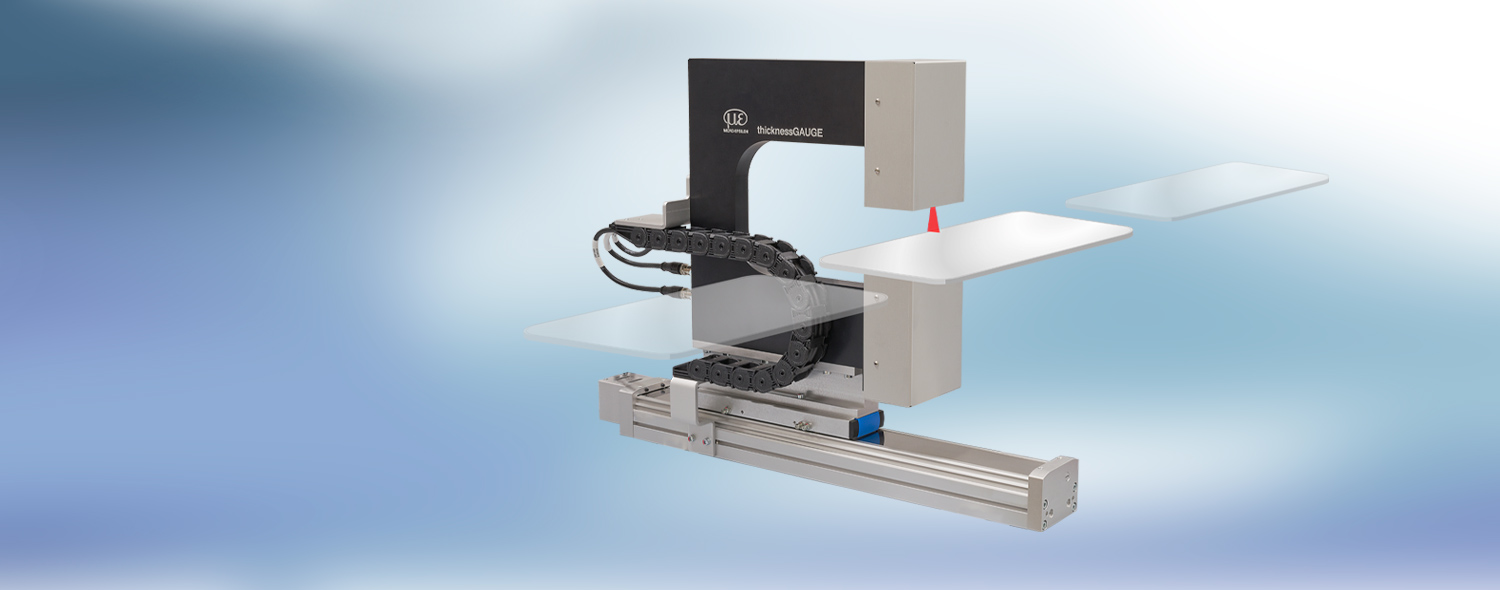

thicknessGAUGE 3D

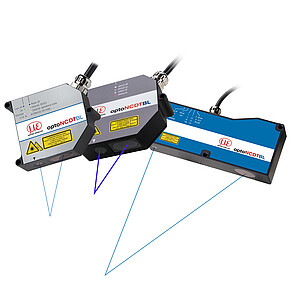

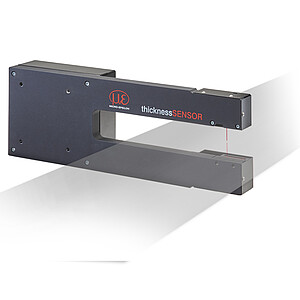

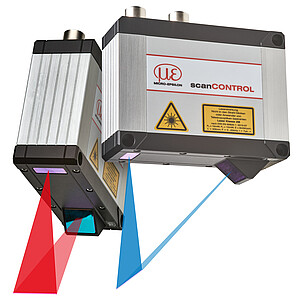

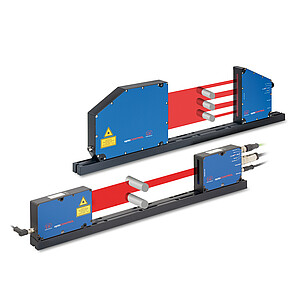

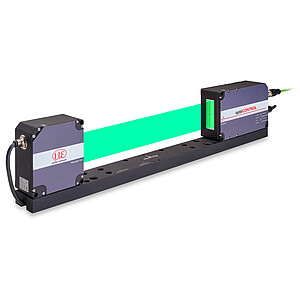

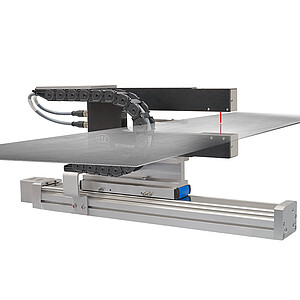

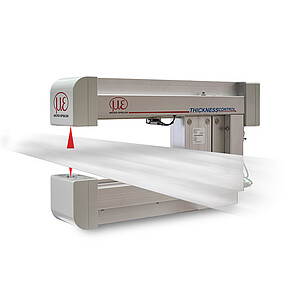

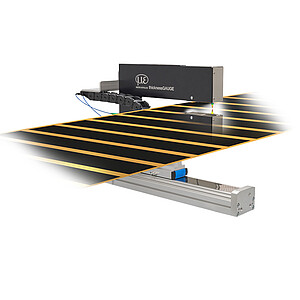

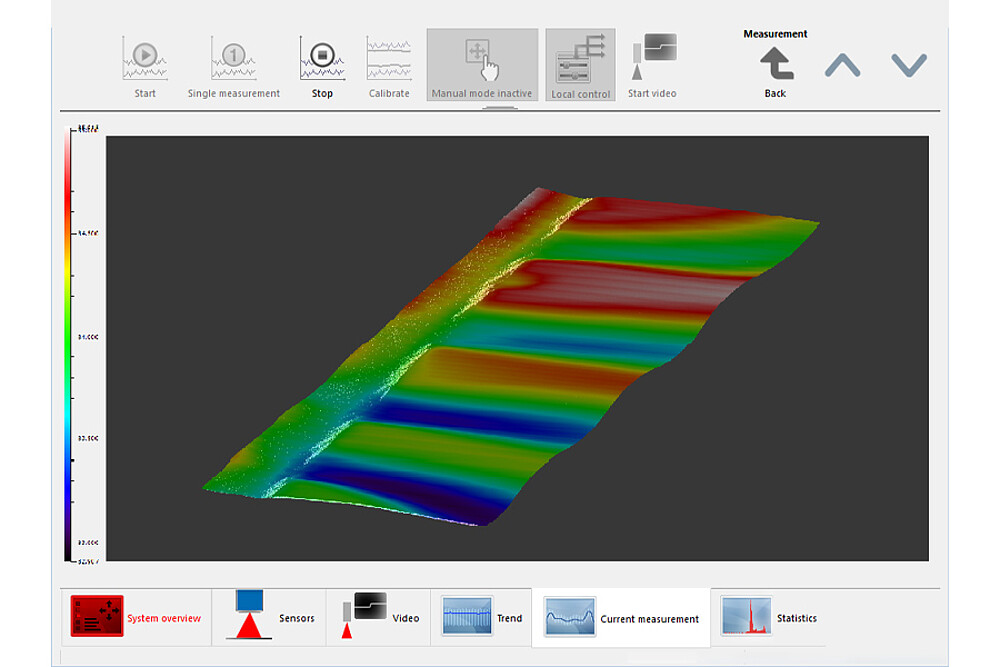

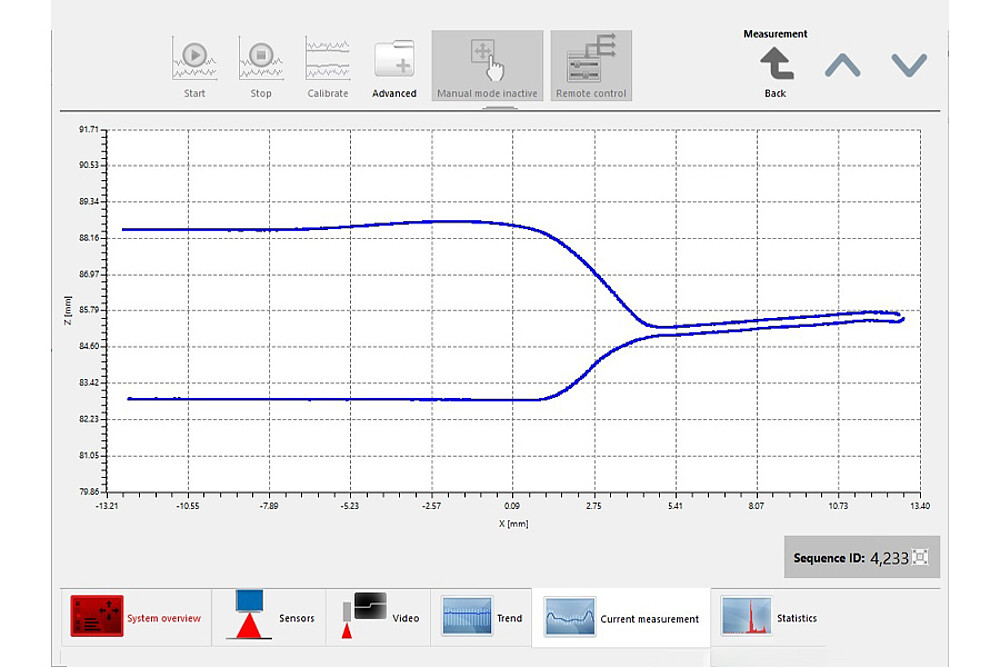

The thicknessGAUGE 3D is a sensor system for inline profile evaluation and 3D measurement of strip and sheet material, e.g. the edge of coating applications, weld seams or strand profiles. It consists of a stable frame with two laser scanners attached to it. The scanners detect the profile of the upper and lower surfaces and enable calculations within the individual profiles as well as combined as a 3D point cloud.

Characteristics

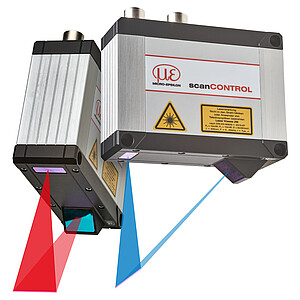

- Sensors used: Laser profile sensors with red laser

- Measuring range: 15 mm (thickness) / max. 26.8 mm (profile)

- Resolution: 0.2 µm (thickness) / 1,024 points (profile)

- Accuracy: +/- 1.2 µm

- Measuring rate: 500 Hz

- Flexible positioning due to electromechanical axis

- Automatic calibration for constant precision

Precise profile and 3D measurement in the line

The thicknessGAUGE sensor systems are assembled ready for operation and calibrated at the factory. In addition, the laser scanners are perfectly adjusted to each other in terms of their mounting conditions, therefore providing high measurement accuracy. The sensor system is moved from the parking position to the measuring position. For fully automatic calibration, the system is moved back to the parking position.

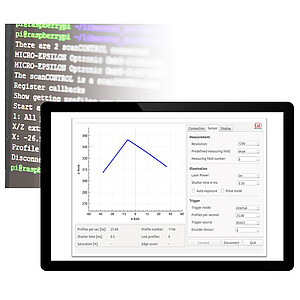

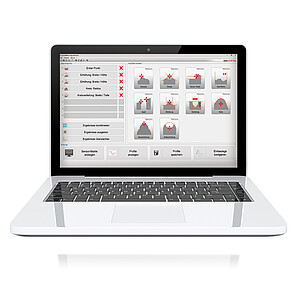

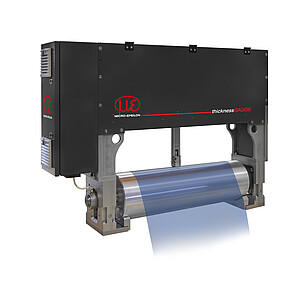

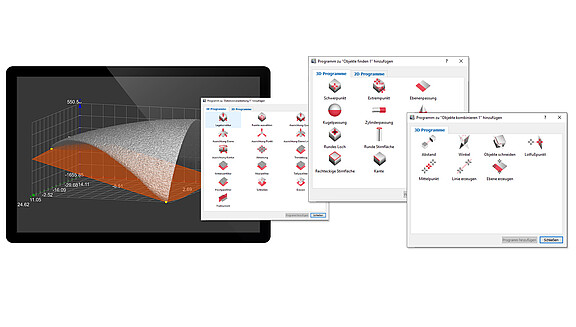

Automatic calculation with extensive configuration options

The measurements are performed automatically with the thicknessGAUGE 3D. This requires a configuration file, which is provided by Micro-Epsilon and imported into the thicknessGAUGE 3D. You can create your own or multiple configuration files using the optional 3DInspect software. Any parameters can be selected in this software and many measuring object geometries can be configured for the subsequent calculation. Powerful tools in the software also allow the alignment and filtering of the point cloud, the intuitive detection and selection of relevant areas and the combination of programs.