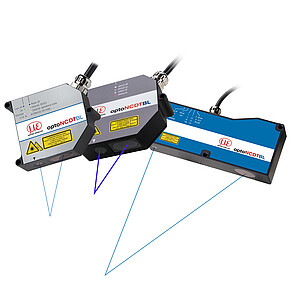

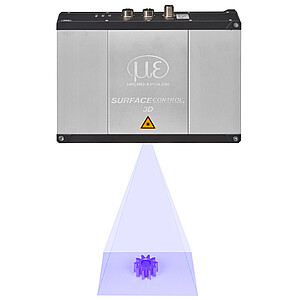

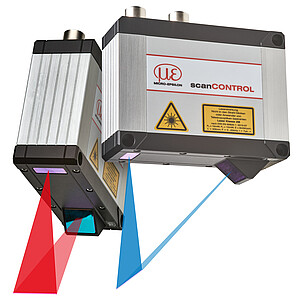

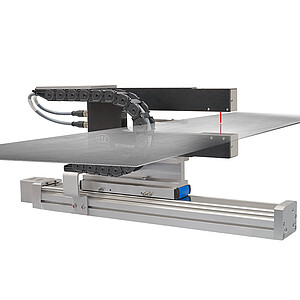

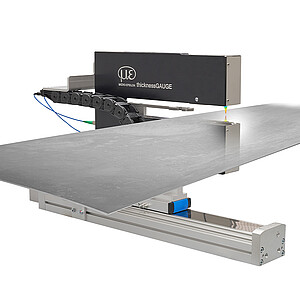

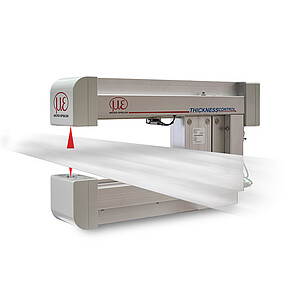

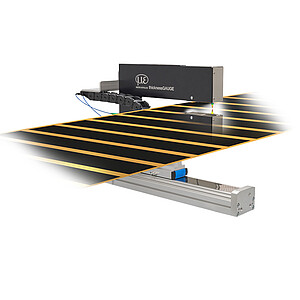

High-precision 3D sensors for inline applications

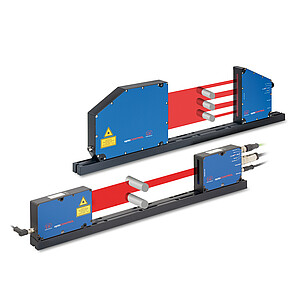

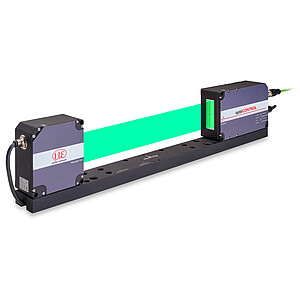

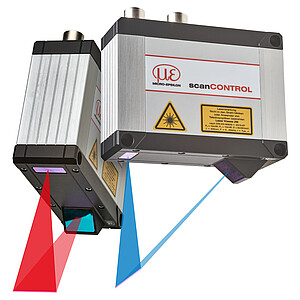

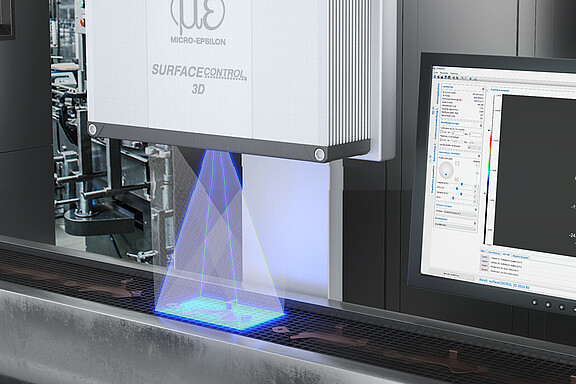

The new generation of Micro-Epsilon snapshot sensors impresses with high accuracy in the 3D measurement of geometries components and surfaces. With the surfaceCONTROL 3500, Micro-Epsilon offers 3D sensors that capture high-precision 3D snapshots in a short time and generate detailed 3D point clouds.

The 3D sensors are used, for example, for inspection, position determination, presence detection and flatness measurement. Thanks to their high performance, the sensors are used for inline applications, on robots and also for offline inspection.

Your advantages at a glance

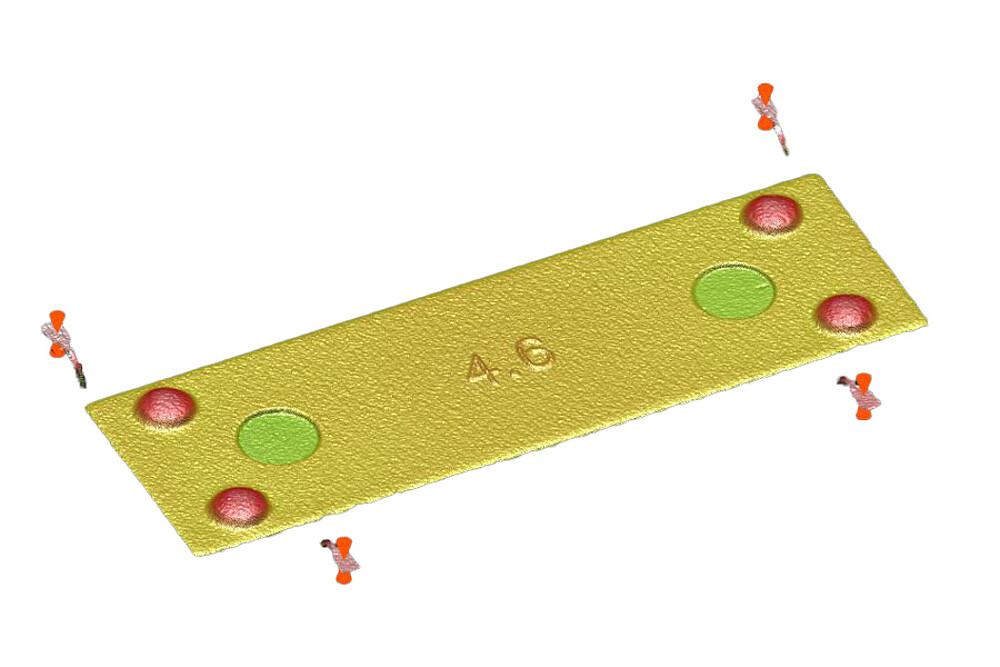

- Highest repeatability up to 0.25 µm

- Best Z-resolution from 0.7µm

- X/Y resolution from 16 µm

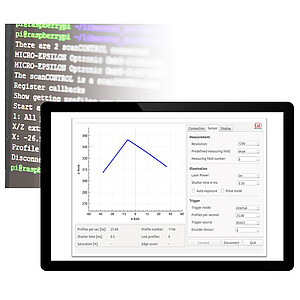

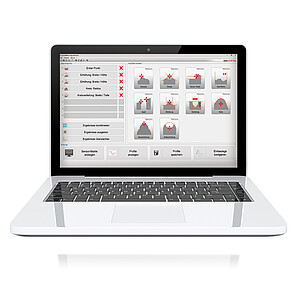

- 3DInspect: Powerful evaluation software with intuitive operating concept

- Fully integrated industrial sensor IP67 with passive cooling

- New 3D GigE Vision / GenICam standard for easy integration into common 3D image processing packages

- Extensive SDK

- 3D data directly from the sensor

Ideal for measurement tasks in industry and automation

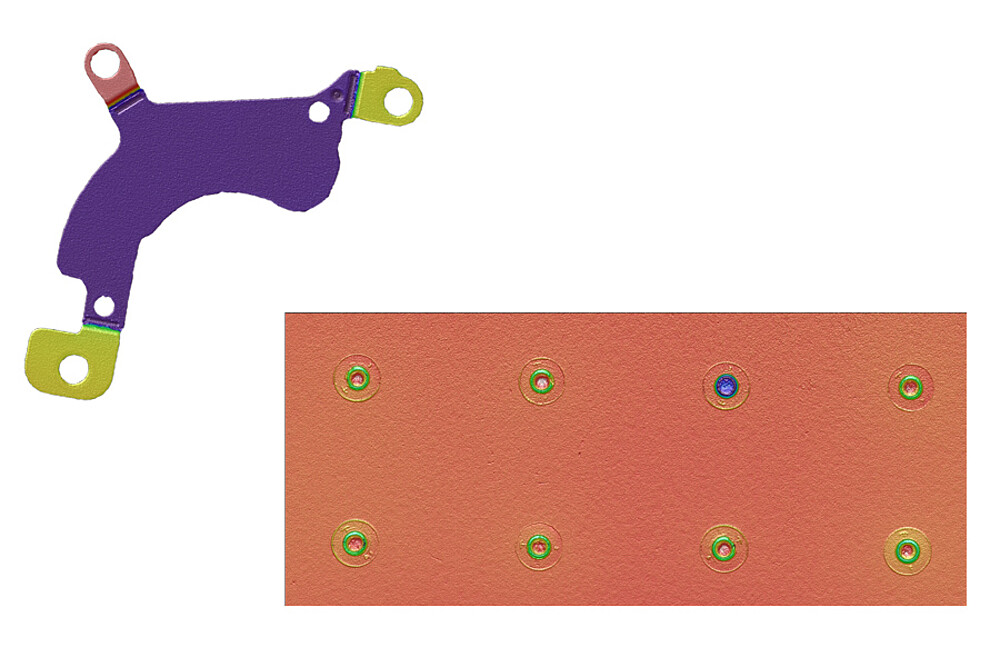

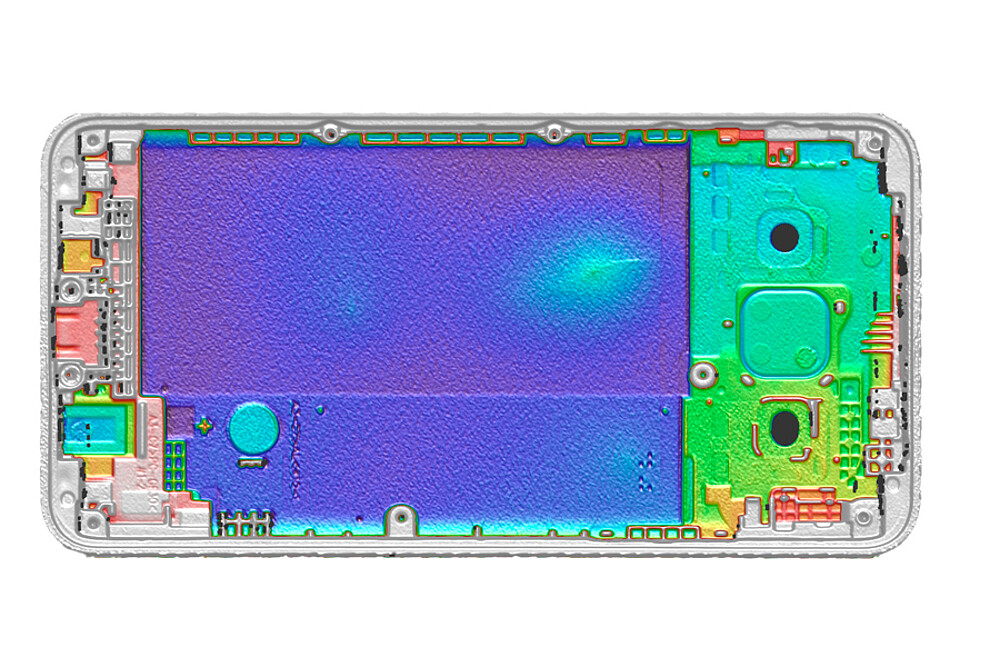

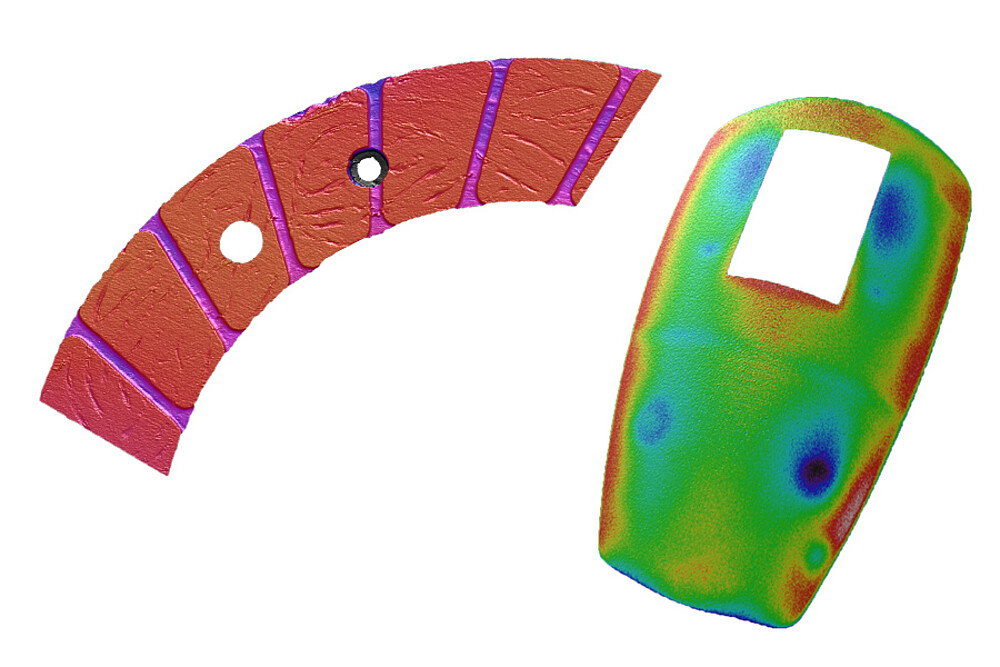

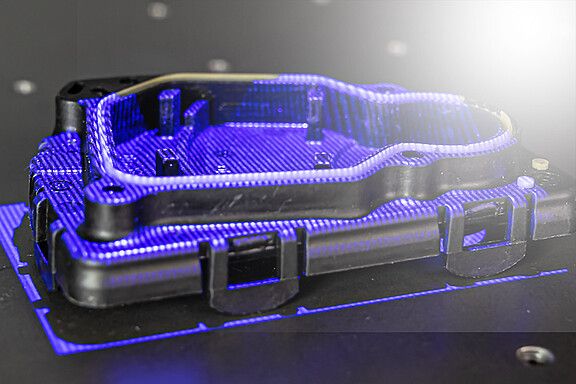

The surfaceCONTROL 3D sensors solve various measuring tasks. These include, for example, the 3D measurement of screw-on surfaces on complex components. Deviations in the shape of the surface of injection-molded parts can be detected. And a very common application is the inspection of printed circuit boards in electronics production - both before and after assembly.

High measuring rate

With the surfaceCONTROL 3D 3500, the projection of the fringe pattern and the recording by the two cameras are completed in around 0.2 to 0.4 seconds, depending on the measurement task. The processor then calculates the 3D point cloud - the measurement object can already be moved on to make room for the next workpiece. The sensor delivers up to 2.2 million 3D points per second.

Wide range of data transmission options

In addition to Gigabit Ethernet (GigE Vision / GenICam), PROFINET, EtherCAT and EtherNet/IP are also possible. There are also four parameterizable digital I/Os that can be used as triggers or to output sensor status, for example.