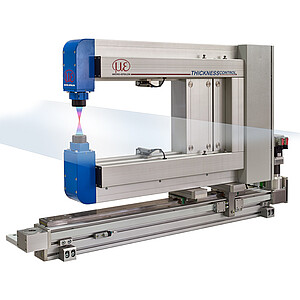

Optical gauges for precise thickness measurements of metals

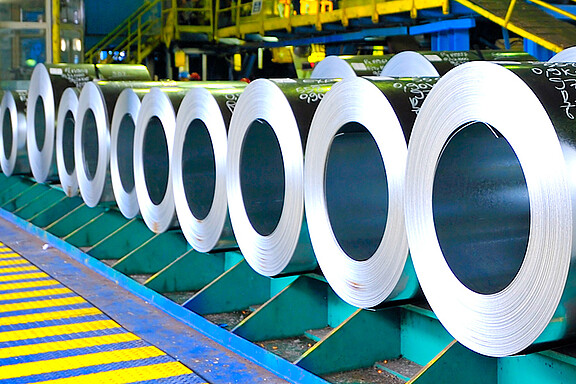

Thickness measurement of metal strips and plates is possible by using radiometric as well as laser-based measurement methods. In recent years, laser-based thickness measurement has become increasingly important and is equally appreciated in the steel and aluminum industries. This is due to the numerous advantages that laser thickness measurement brings: improved measurement accuracy, all alloys without complex calibration, thin and thick metal strips - and last but not least easy operation without radiation protection measures.

Systems for thickness measurements of metal strips and plates

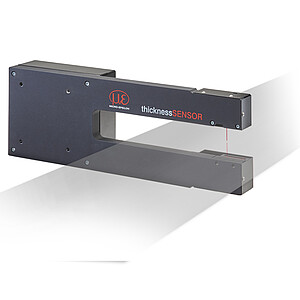

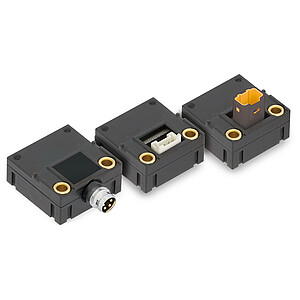

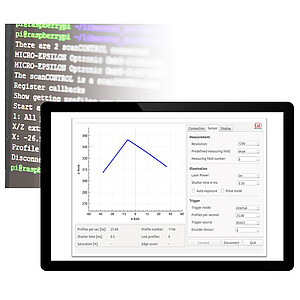

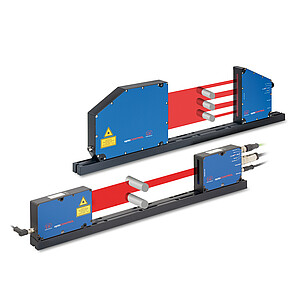

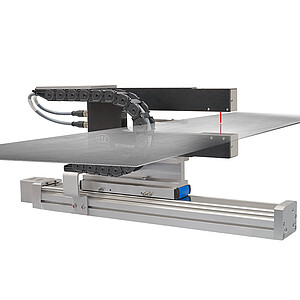

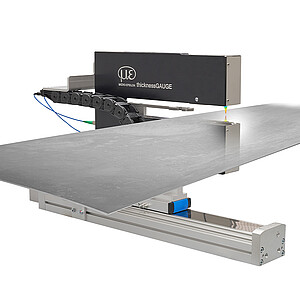

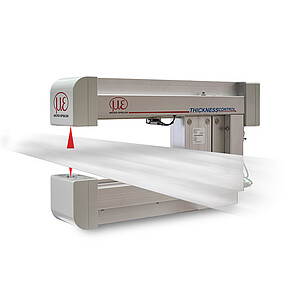

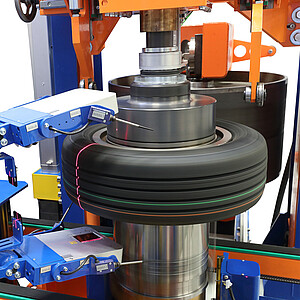

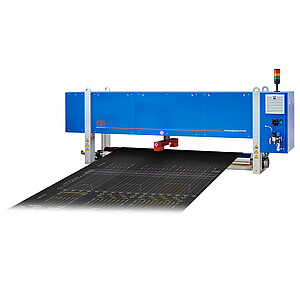

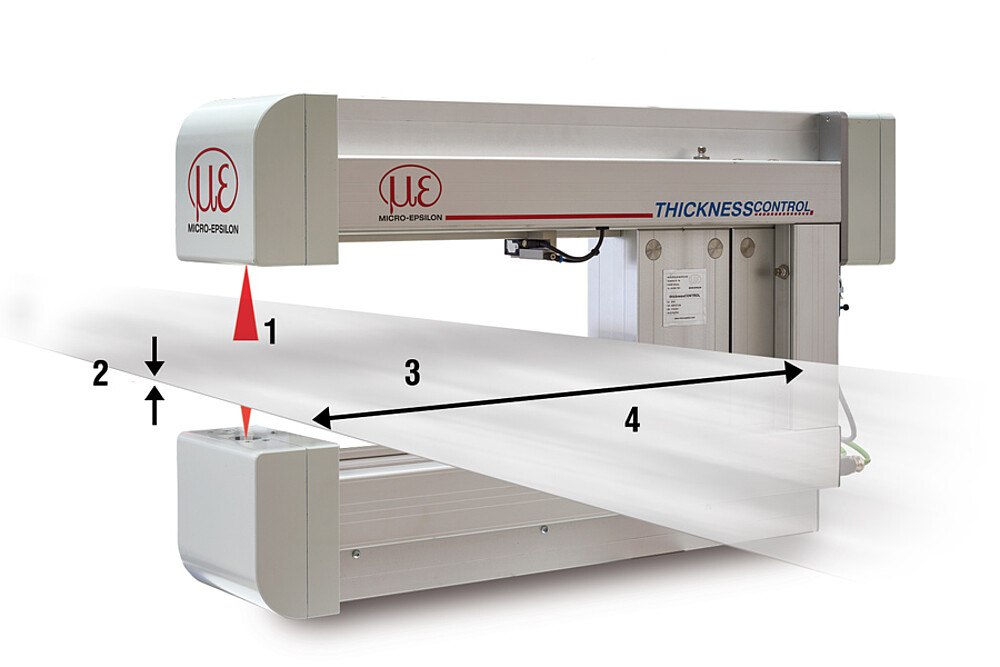

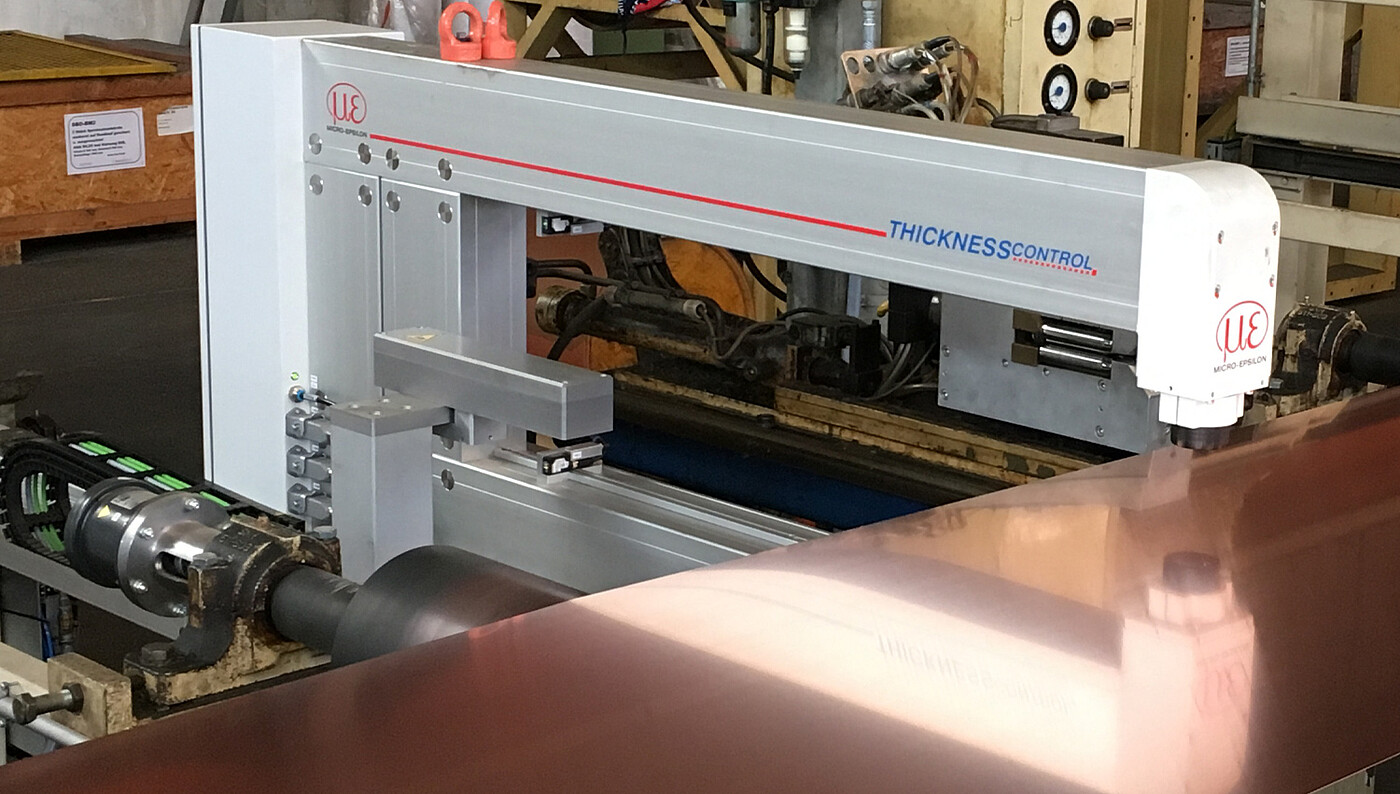

For thickness monitoring of metal strips and metal plates, Micro-Epsilon offers measuring systems and optical gauges with application-specific sensors. Depending on the model, the systems can be used in cold or hot rolling mills. For traversing bandwidth monitoring, O-frame systems are used, while C-frame systems are used to measure individual tracks.

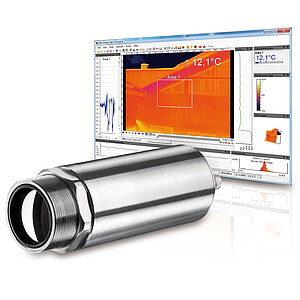

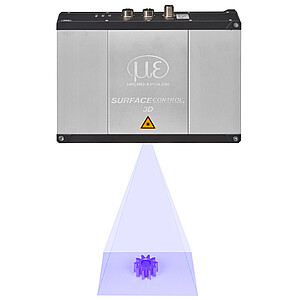

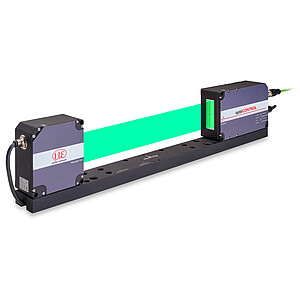

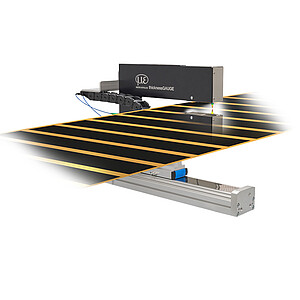

Innovative laser line technology

Laser line technology offers several advantages: signal gaps caused by steam or particles do not affect the measurement. Sheet tilting can also be detected and compensated for. As a result, the thickness accuracy is identical for flat sheets and tilted sheets. The laser line can also detect sheet edges.

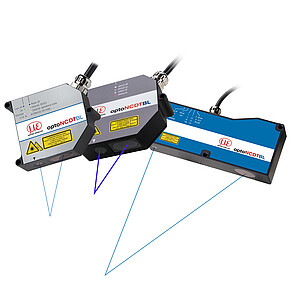

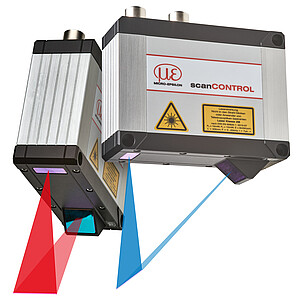

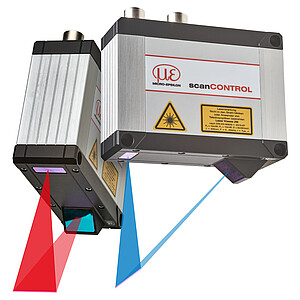

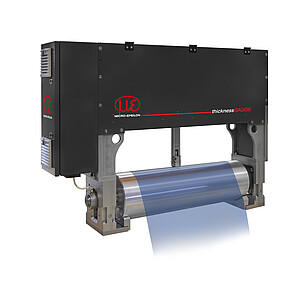

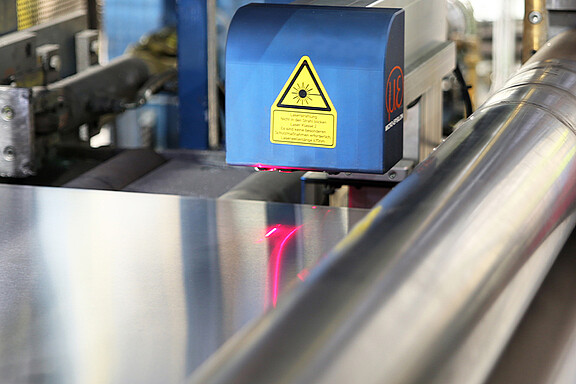

Optical gauges for highest precision

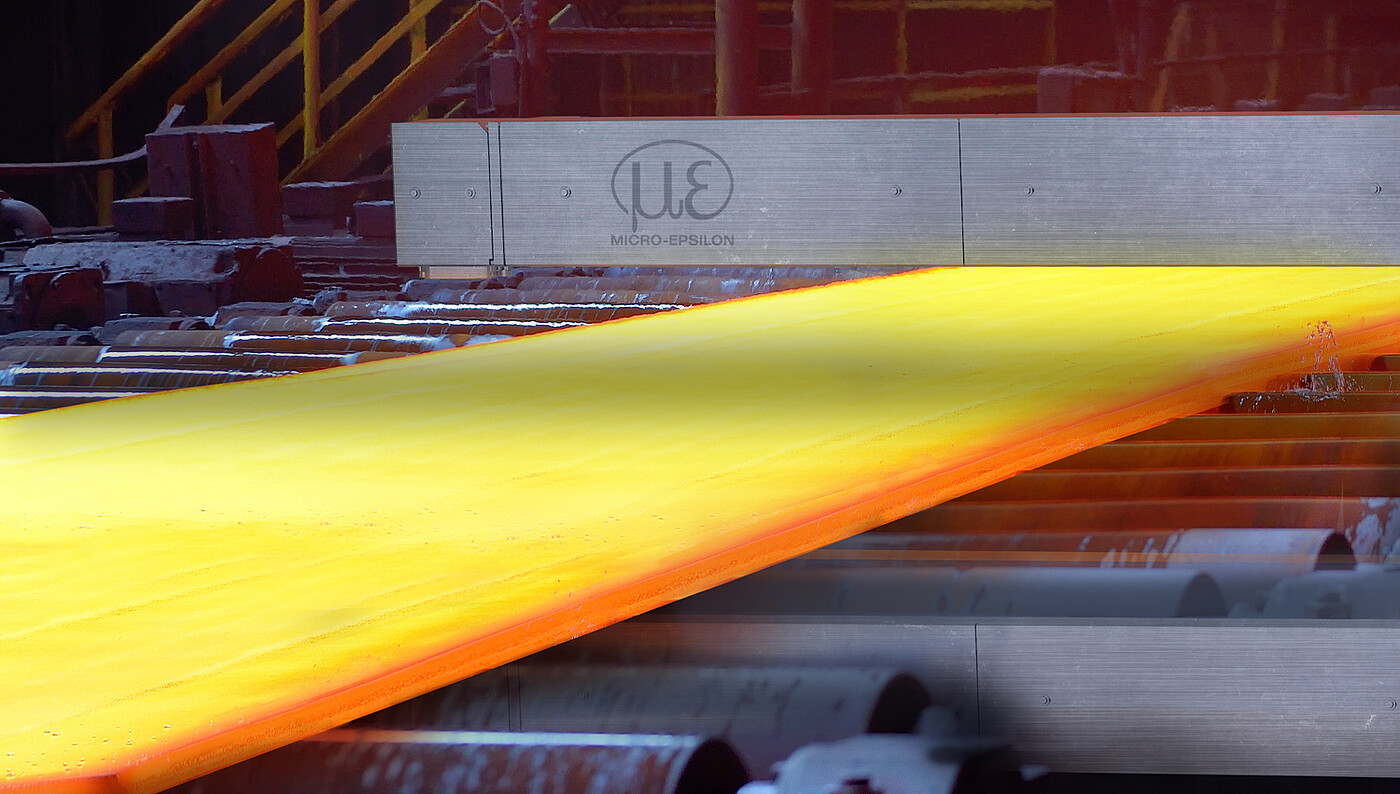

The laser scanners preferred in the thicknessCONTROL systems offer numerous advantages in thickness measurement. Two types of laser are available - the red laser is used for measurement tasks in the cold rolling area. The patented Blue Laser technology is used in the metal industry, especially for red-hot metals. The blue laser light uses a different wavelength range than red laser light, which means that the laser line is formed sharply on the measuring object and is focused sharply on the sensor element. Special filters prevent the sensor from being blinded by the radiation of the glowing target. This results in much more stable and reproducible measurement signals.

Advantages at a glance

- High accuracy, alloy independent

- No radiation protection required, no waste disposal costs

- Only one system for both thin and thick objects

- Money-saving and environmentally friendly (no radiation)

- High measurement accuracy even in harsh environments

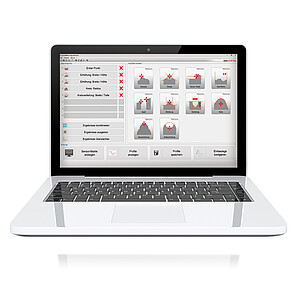

The alternative for radiometric measurements

Laser-based systems from Micro-Epsilon are much easier to use than radiometric systems. As this type of thickness measurement is independent of materials or surfaces, alloy compensation is not necessary. To compensate for temperature-related effects, the systems are equipped with fully automatic calibration. The calibration process is extremely fast and happens between two slabs.