Precise sensors for glass measurements

Due to their high accuracy and measurement speed, sensors from Micro-Epsilon are used in the glass industry for numerous measurement tasks. For example, robust eddy current sensors are integrated into machines in order to detect machine movements while optical sensors monitor glass products directly in the processing line. Typical measurement parameters include displacement, position, thickness, color and temperature.

The following applications cover just a few application examples. Please contact us for further informations.

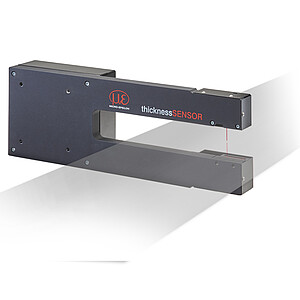

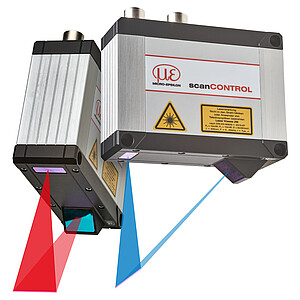

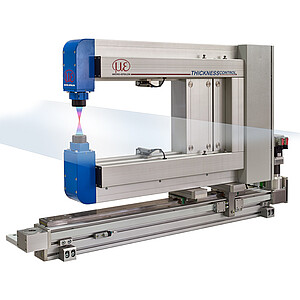

Thickness measurement of displays and flat glass

For the production of display glass, glass sheets with a homogeneous thickness profile are required. For thickness measurement tasks, confocal chromatic sensors from Micro-Epsilon are used. These detect the thickness from one side without touching the target. Due to their high measuring rate, the sensors are also applied in high speed processes.

Confocal sensors for display measurements

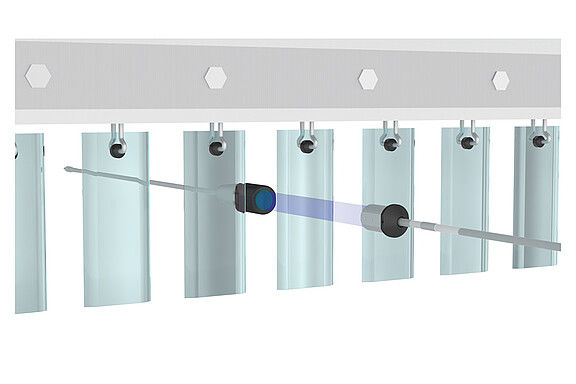

Gap monitoring of safety glass

For quality inspection and process control during the production of safety glass, confocal chromatic displacement sensors are used which offer a multi-peak feature. These enable thickness measurements to micron accuracy. The sensors detect up to 5 layers by evaluating 6 measurement values on the boundary areas. Therefore, the thickness of film, gap sizes, applied adhesives and coatings can be determined reliably.

Thickness measurement of medical container glass

Consistent thickness of walls and bottom are vital quality factors in medical container glass. In order to determine the glass thickness, confocal chromatic sensors from Micro-Epsilon are used. These sensors also measure very thin glass. Thanks to thickness calibration, the distance between the containers and the sensor can vary without affecting the measurement accuracy

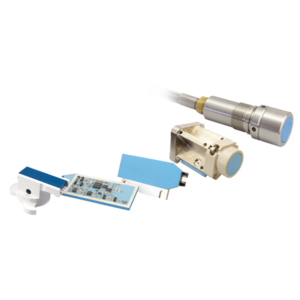

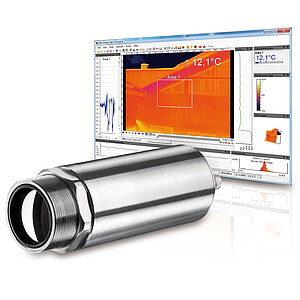

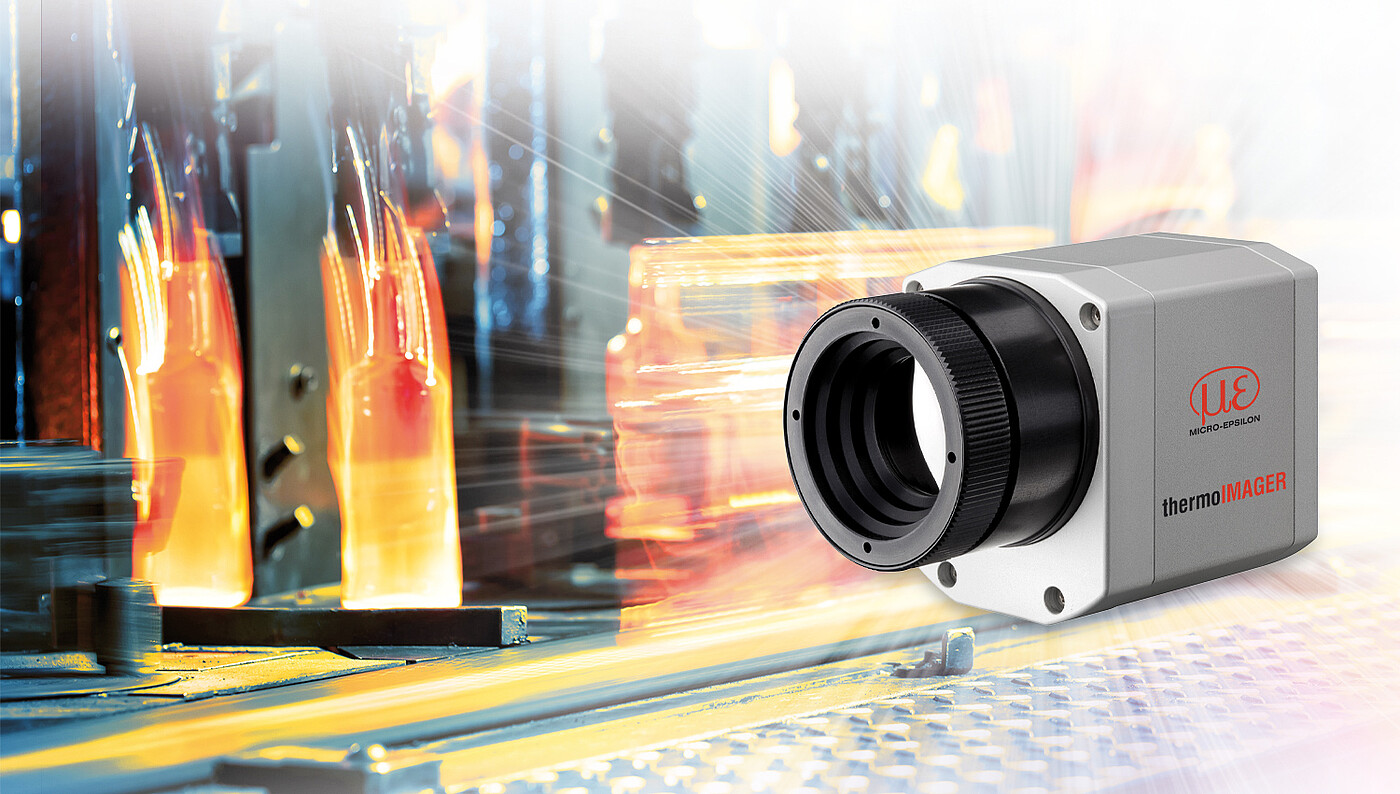

Non-contact temperature measurement during the shaping process

In container glass production, the process relevant temperature must be inspected at different points. Non-contact temperature sensors from Micro-Epsilon are used during the shaping process that involves temperatures in excess of 500 °C. When the containers leave the heating zone, the cooling process is monitored using non-contact temperature sensors. As the shaping process lasts for just a few seconds, the sensor response time is critical.

Color measurement of glass

The color of glass is the crucial and visually distinctive feature of many different glass products. This is particularly true with natural and recycled raw materials based on varying compositions, where continuous and objective control of the color effect is a decisive factor in consistent, homogeneous quality. Color sensors from Micro-Epsilon are used in order to inspect colors and shades in the production process.

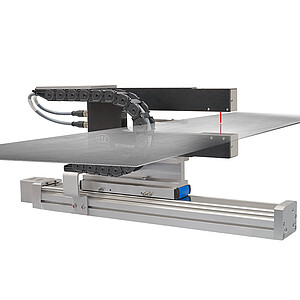

Position measurement when fitting precision glass

In addition to single-peak distance measurements, the white light interferometers are also used for multi-peak distance measurements. This means that both distance values and calculated thickness values can be used to control positioning tasks with maximum precision.

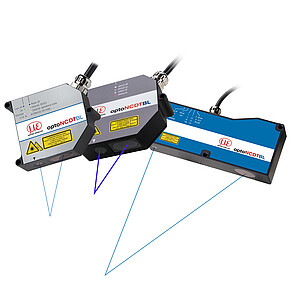

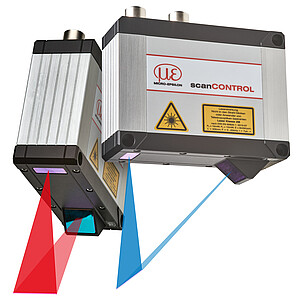

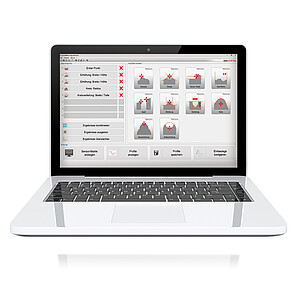

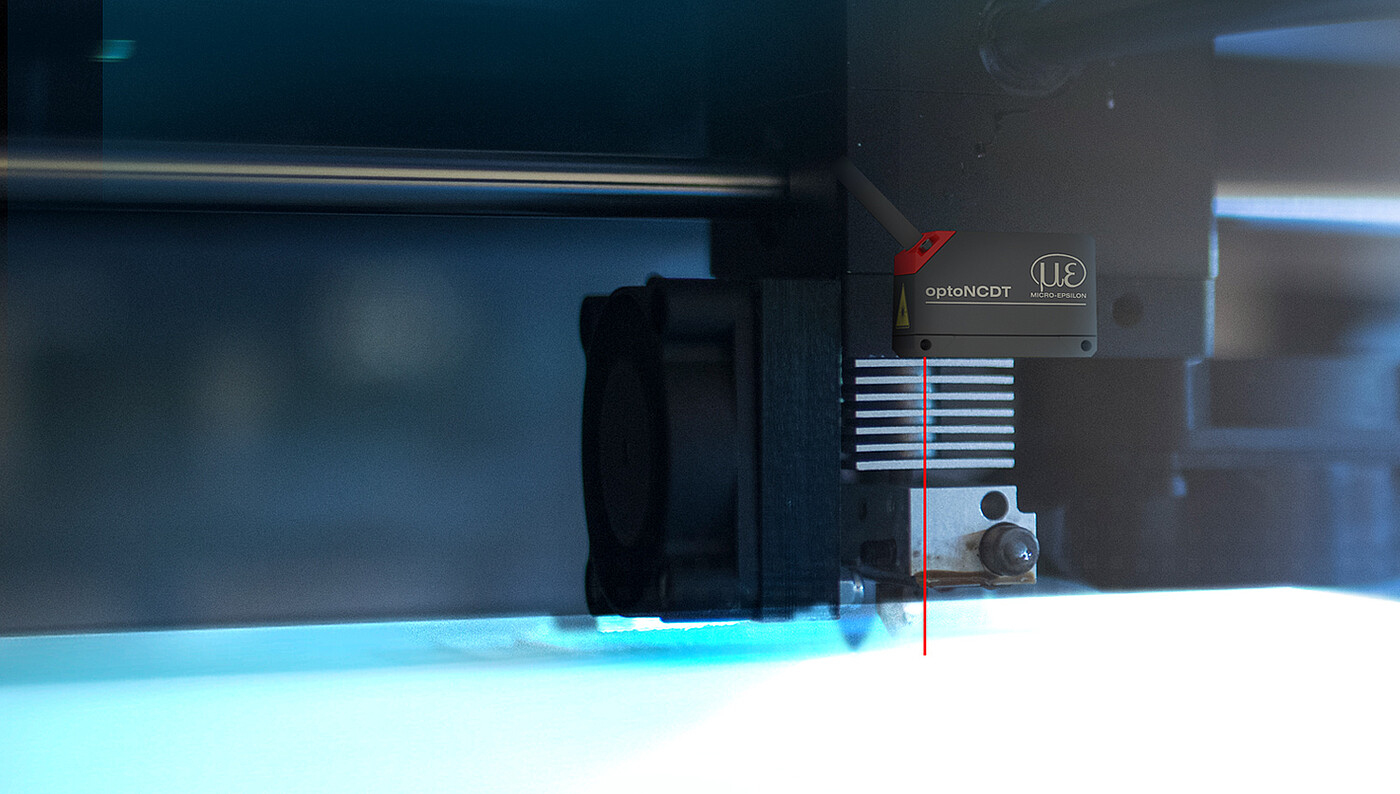

Distance control of print heads for glass printing

When printing on materials such as glass and ceramics, very fine detailed structures are applied on the carrier material, which requires precise positioning of the print head. For distance measurements, optoNCDT 1420 laser triangulation sensors from Micro-Epsilon are used. With a measuring range of 10mm, these determine at various points in the print head the respective distance from the surface to be printed. The data obtained enables the determination of the edges and the surface tilt and therefore the exact positioning of the print head.

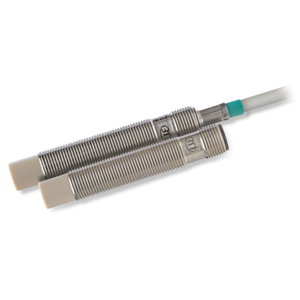

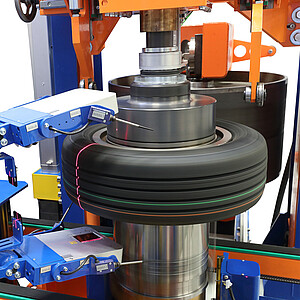

Plunger measurement in IS machines

In hollow glass production, IS machines are used. This production environment is characterized by harsh ambient conditions such as vibration, steam and high temperatures. Micro-Epsilon has developed an inductive EDS displacement sensor, which is specially intended for 24-hour operation in IS machines to determine the exact plunger position. The robust sensor design compensates for temperature influences, including those caused by temperature gradients along the measuring range.

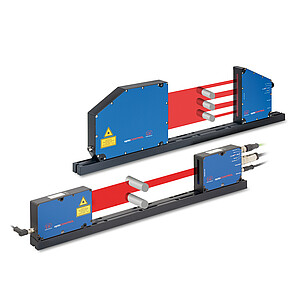

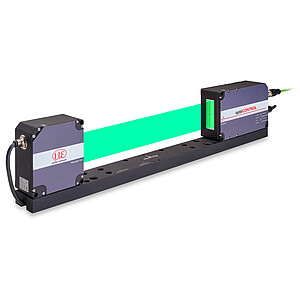

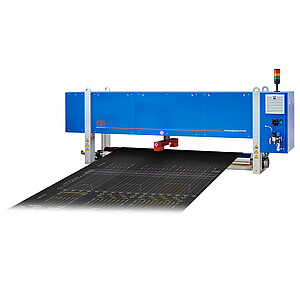

Distance measurement on anti-reflective coated glass

After the coating process, glass with anti-reflective coating is inspected using laser-optical displacement sensors from Micro-Epsilon in order to determine undulations and torsion. The planarity of the coated glass surface is measured in several tracks. Based on the patented Blue Laser Technology, optoNCDT 2300-2DR sensors provide high measurement accuracies on coated glass surfaces.