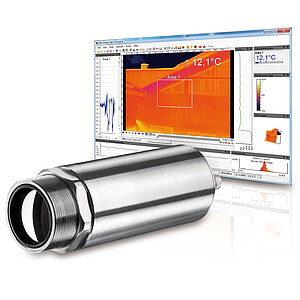

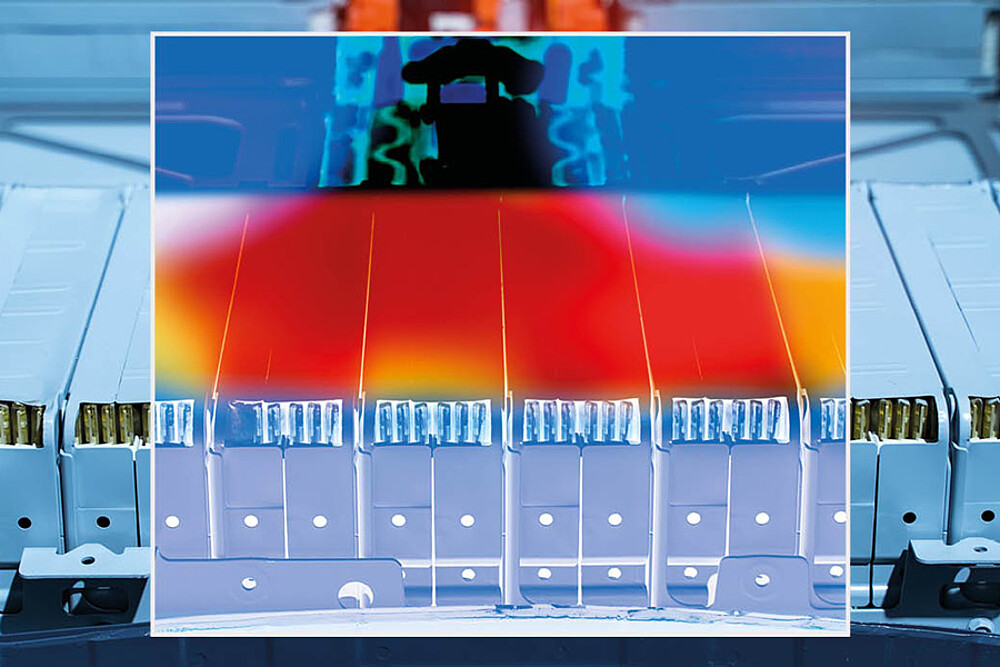

Sensors for the production of electrodes and batteries

In order to optimize the battery production, sensors are required which monitor the production line to the highest accuracy and dynamic. Micro-Epsilon offers reliable solutions from high precision distance sensors to infrared temperature measurement technology and 2D/3D profile sensors for multiple measurement tasks involved in battery production. This website provides examples of applications for Micro-Epsilon sensors within the various stages of production.

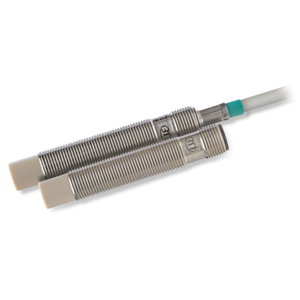

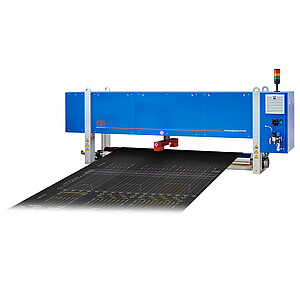

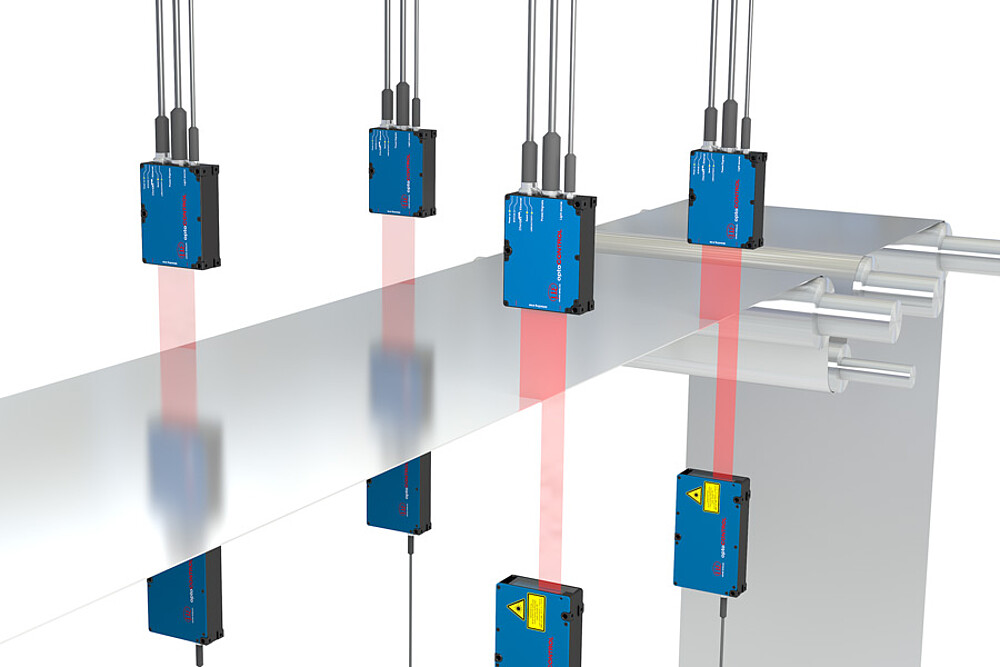

Two-sided thickness measurement using capacitive displacement sensors

Capacitive sensors are used for inline thickness measurements of films, strips and webs. Due to their high temperature stability, these sensors are ideal for dry coating processes. Two capacitive sensors installed opposite to each other perform two-sided thickness measurements of electrically conductive materials. This method is used to measure strip thickness down to the µm range. Each of the two capacitive displacement sensors provides a linear output signal depending on the sensor surface and target surface. As the distance between the two capacitive sensors is known, the thickness of the measuring object can be determined easily. Due to the capacitive measuring principle, the measurement is carried out on the surface without penetrating the object to be measured. The measuring spot of the sensors is larger than those of the optical methods, which averages out any anomalies on the surface.

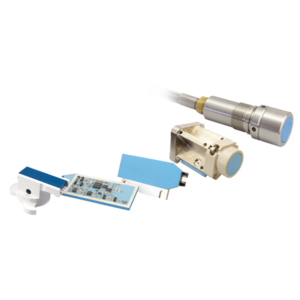

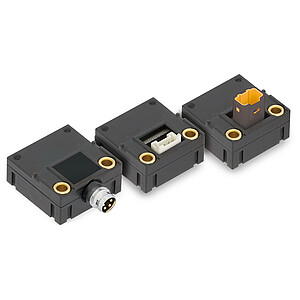

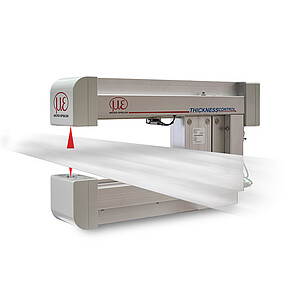

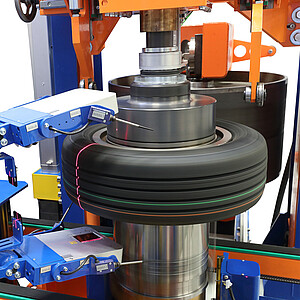

One-sided thickness measurement of films

For one-sided thickness measurement of insulators, the combiSENSOR from Micro-Epsilon is used. This sensor matches two measuring techniques: a capacitive and an inductive sensor (eddy current). The eddy current sensor penetrates the coating and measures the distance to a metallic material underneath it, e.g. a transport roller. Simultaneously, the capacitive sensor measures the thickness of the coating (e.g. graphite). The thickness is determined based on the difference of both sensor signals. In addition to absolute thickness measurement, high measurement accuracy and compensation for distance variations offer further benefits.

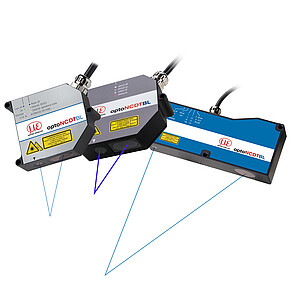

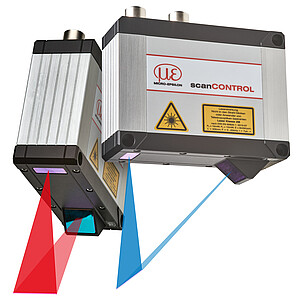

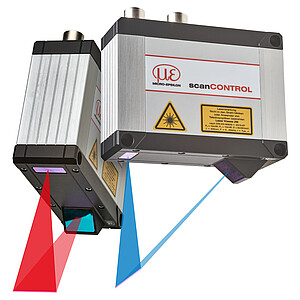

Strip thickness measurement using confocal chromatic sensors

Confocal chromatic distance sensors detect the thickness of different objects using the differential thickness method. The measurement can be performed on different targets, e.g. plastic films, metal strips or coated materials. The use of confocal chromatic sensors enables a measurement resolution in the submicron range. Due to their high measuring rate, even high speed processes can be monitored reliably. Confocal sensors are typically used to monitor and control wet coating processes, but are also suitable for thickness monitoring in dry processes. In addition to individual sensors, Micro-Epsilon also offers complete systems with integrated sensor technology, mechanics and auto-calibration.

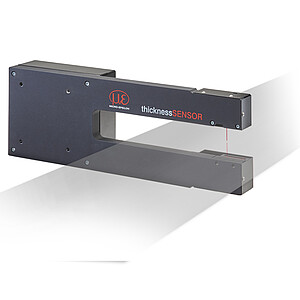

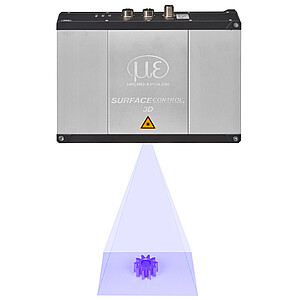

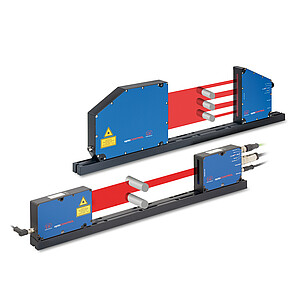

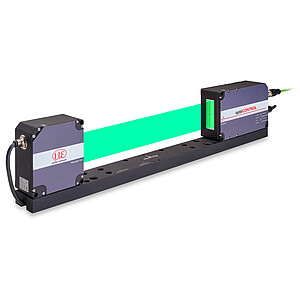

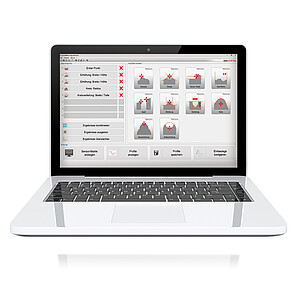

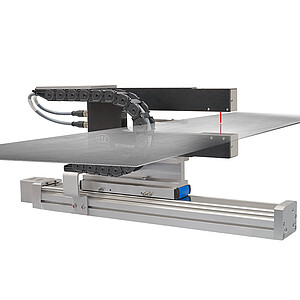

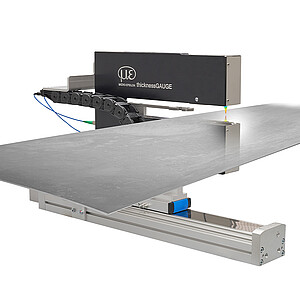

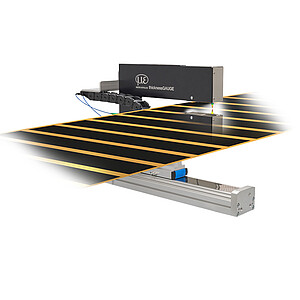

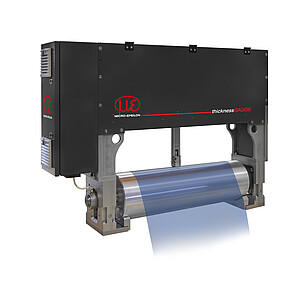

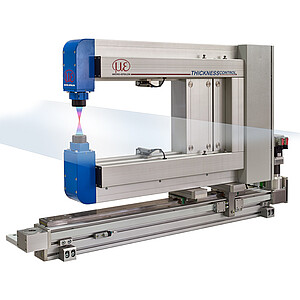

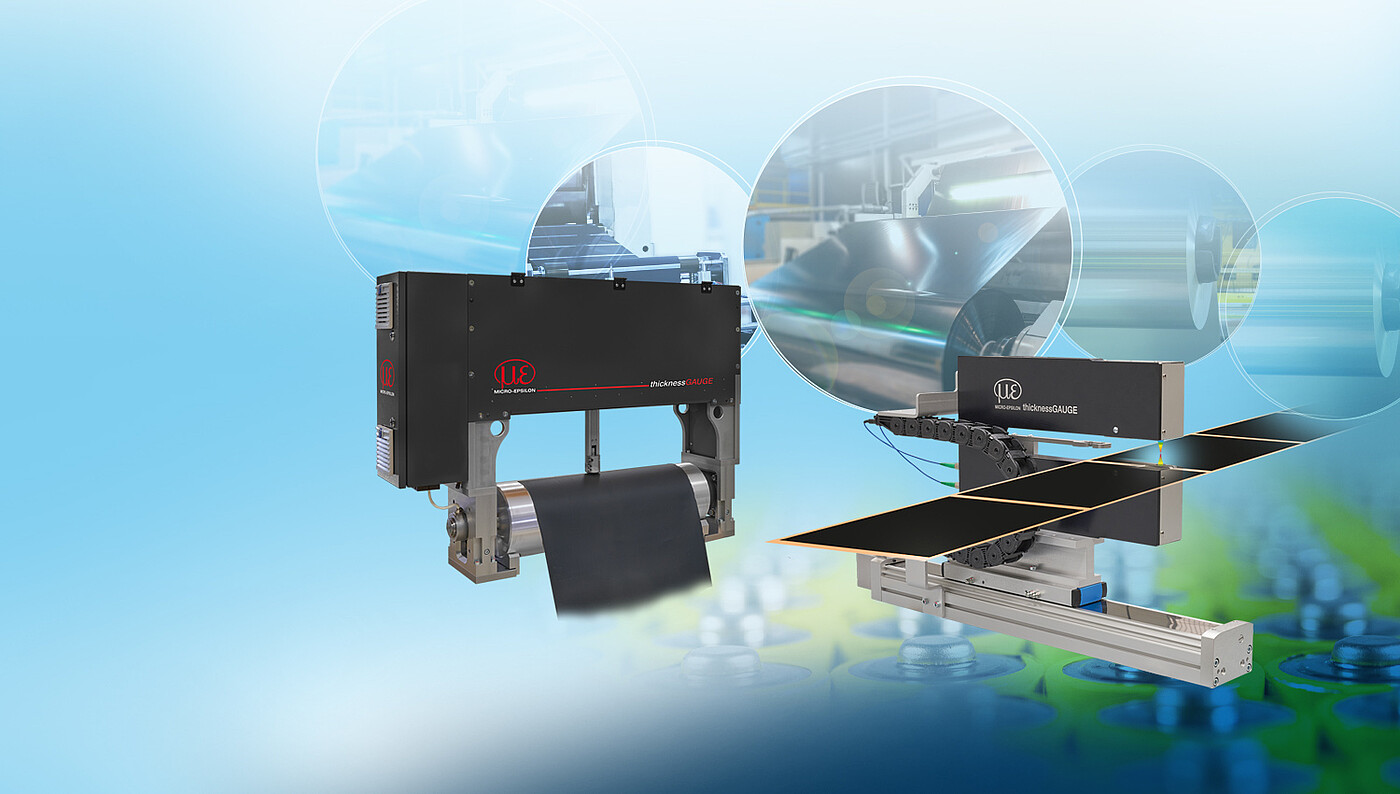

Precise systems for inline thickness measurements

ThicknessGAUGE sensor systems are used for inline thickness measurement of strip materials. These are available with different sensor types, measuring ranges and measuring widths for the thickness measurement of different materials and surfaces. The thicknessGAUGE systems use two optical or electromagnetic distance sensors to detect the strip thickness. The sensors are perfectly aligned to each other and calibrated. Furthermore, thickness calibration at the factory ensures high precision. By means of a linear axis, the thicknessGAUGE sensor systems can be moved to measure the thickness across the entire strip width.

The thicknessGAUGE O-frame systems are frequently used in dry coating at high ambient temperatures. Equipped with the patented combiSENSOR measurement technology, the systems deliver precise thickness measurements with high long-term stability.

Get your white paper now!

Discover how other manufacturers are already benefiting from modern sensor technology and gaining a clear advantage over their competitors.

Learn from numerous real-world use cases how you can save costs and reduce error rates with high-performance sensors and measuring systems.

Use this whitepaper as a guide to optimize your strategy.